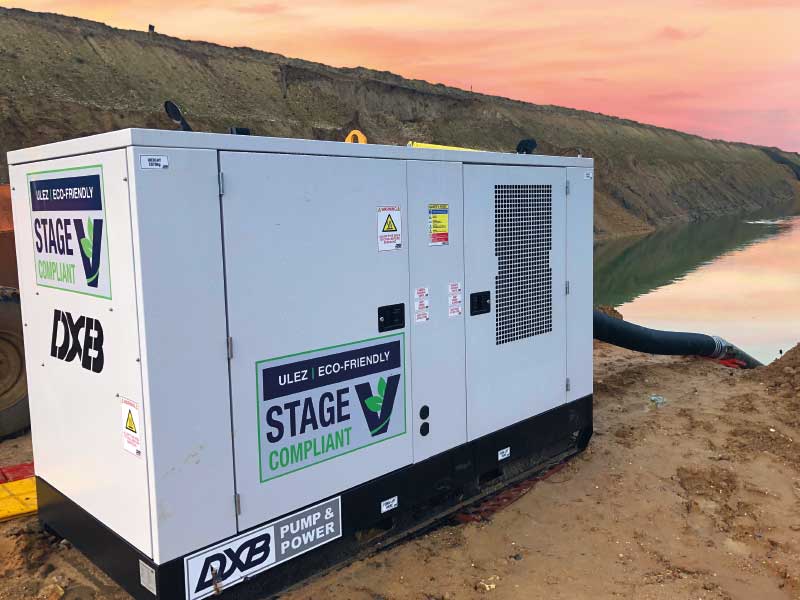

DXB Pump & Power, the UK’s newest pump manufacturer, launched its new Stage 5 emission compliant range of pumps for use in European Mines and mining contractors throughout the EU.

The pumpsets have been designed with German Deutz engines below 250kw and Scania 13 litre and 16 litre engines all with Stage 5 aftertreatment and housed in environmental, sound attenuated and fully bunded canopies to ensure they meet the strictest emission laws on the Continent. Designed in house and manufactured in the UK only using premium components from leading manufacturers, the DXB Pump range of pumps starts at 18kw for their high flow 100mm and 150mm low head pumpsets right up to the 475kw Scania powered 8X6 pumpsets capable of flows in excess of 750m3/hr and heads of more than 200m. Available in ten sizes all with integrated fuel tanks, single or four point internal lifting frames, and then available as skids, hooklifts, and trailers. All of DXB pumps use the worlds leading self-priming REDIPRIME pump from Cornell in the USA, the recognised leader in the types of pumps used in major mines all over the planet.

Simon Ruffles, Owner and Managing Director of DXB Pump & Power, said…

“The DXB Pump product range is the largest range of dry prime pump range of any manufacturer in the World, with over 70 models of pumpsets available for various applications throughout the World. With our unique modular design programme we can offer a high pressure dewatering pump, a high flow dewatering pump, a slurry pump and finally a CD4MCu Duplex stainless steel pump in every single Stage 5 pumpset without having to change any other component such as the engine or control systems- this is unique in the mining world today and will reduce the spares, maintenance, and downtime of pumps on any mine.”

Combining Cornell pumps from the US market leading manufacturer and the skills that DXB Pump have learnt over the last twenty years, the company has designed and now manufacture a comprehensive range of pumpsets. Which are able to dewater mines in hostile locations such as the Arctic Circle mines seen in Scandinavia and Canada, where some of the features included in the DXB pumpset like satellite telemetry enable their customers to remotely monitor the pumpsets from the comfort of the office or cab of the loader as well as the DXB offices in the UK.

Simon Ruffles continued…

“Minimising downtime on our customers mines is business critical for us and we have designed these pumpsets for them to know about issues before they actually happen. With the use of telemetry technology, our customers and us can monitor all aspects of the engine and pump operation including the flow, pressures and suction characteristics of the pump end in addition to the welfare of the engine. This is critical to ensure that service and maintenance is undertaken in an appropriate time but also minimises downtime due to the unexpected.”

Outside of the EU mining markets, DXB Pump through the major procurement houses in Europe won a £1.2m contract to supply mine dewatering pumpsets to a major international mine in Africa. The project was a major challenge to DXB as the delivery date agreed with the client was twelve weeks.

With engines from Caterpillar specified and the Pretoria factory already working flat out, DXB Pump and Power contacted a number of CAT dealers around the world and sourced suitable CAT C15ACERT 375kw engines which required airfreighting to the company. Rescheduling their production programme, DXB Pump and Power brought the twelve portable 500m3/hr pumpsets straight into production with extensive additional design work being undertaken in house to complete the features that the mine requested and ordered including fast fuelling systems, suction booms and trailer configuration as well as full safety lighting on the pumpsets as well. Within a week all the design work had been completed and orders issued for a dozen 6mm steel box section fuel tanks with 1000 litre capacity ensuring that the company to begin building the pumpsets within the following four weeks to ensure on time delivery.