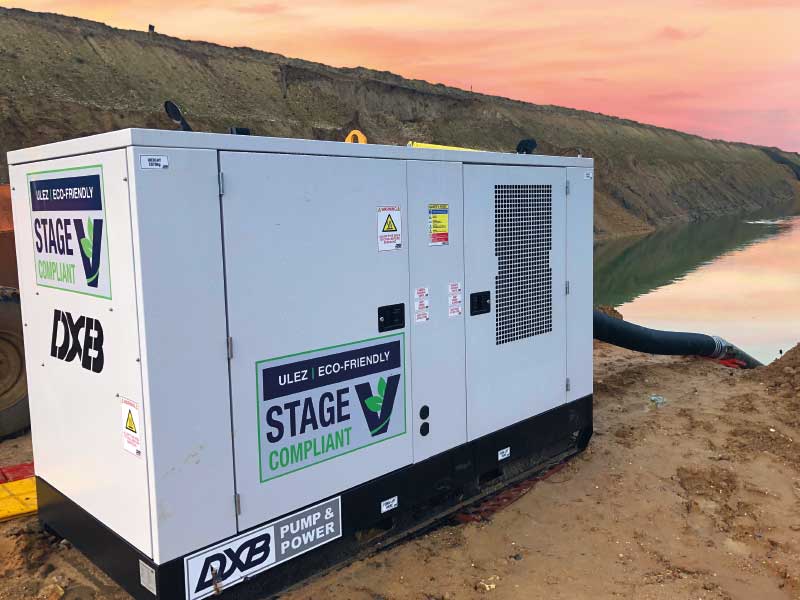

DXB Pump & Power expand their Stage 5 range of Geotech pumpsets to satisfy changing market demand

UK based and owned DXB Pump & Power, has expanded its range of Stage 5 emission compliant pumpsets for the Geotech sector with the launch of the SS300/70 wear resistant Stage 5 100mm pumpset this month. Specifically for the piling, tunnelling and drilling applications seen on HS2, the new pumpset combines a hard-iron, wear resistant pump directly coupled to a Deutz TCD3.6 Stage 5 emission compliant engine producing 95kW at a fuel efficient 1800rpm and managed by the DXB in-house designed control panel with full telemetry. Mounted in a fully bunded, sound attenuated canopy complete with HotBox, the unique design of the pumpset, remotely mounts all of the hot exhaust after treatment equipment (EAT) in its own compartment away from the engine bay allowing for higher temperature operation seen in the summer months on construction sites without shutting down due to overheating. Dave Rodgers, Director of UK Key Accounts, commented… “We have tested two pumpsets on the UK construction market for over six months now and the feedback speaks volumes when your customers do not want to off-hire them even when they have no specific job for a short time between projects. This pumpset combines very low fuel consumption and zero damage charges for our customers in the Geotech sector where historically they have used thirsty, older engines and then paid for worn out parts because the fluids damaged the pumps costing several thousand pounds- that way of doing business is now dead. With the Deutz Stage 5 engine, the DXB pumpset use 80% of available power at all speeds which means they keep the engine hot, reducing soot and ash build up in the exhaust after treatment (EAT) systems but at the same time monitoring the whole system on our pump telemetry and in our national control centre in Nottingham.”” The compact units are designed and manufactured in the brand new 12,000sqft DXB factory in Suffolk which is currently producing up to 35 pumpsets a month for the UK equipment hire industry. Simon Ruffles, Managing Director of DXB said, “Stage 5 engines are absolutely the way to go if customers want to reduce their fuel consumption and costs therefore emissions. We are now the market leader in these pumpsets and have been developing our range since BAUMA 2019 so right now, only we offer a complete range of dewatering and Geotech pumpsets for major projects like HS2 and Thames Tideway where dewatering, tunnelling, piling and drilling customers are all demanding Stage 5 engines.” The company has not though stopped at Stage 5 engines, and offers these pumpsets with IEC4 high efficiency electric motors as well where power is already or will be available for site equipment meaning they will be zero emissions, something no other pump company can do at this time. NOTE: THE SS300/70 pumpset is a 150x100mm pumpset that weights less than 3000kg and is powered by the Deutz TCD3.6 engine with 500 hours service intervals. The pumpset has a 450 litre fuel tank and Fuel Active technology ensuring best fuel consumption and reduced emissions. The pumpset has a maximum flow capability of over 300m3/hr and maximum pressures in excess of 7 bar whilst still handling the higher specific gravities seen in drilling fluids which can lead to competitors engine overload and shutdowns on site.